How to Maximize Efficiency with Li Metal Battery Technology

Table of Contents

- Understanding Li Metal Battery Technology Fundamentals

- Advantages of Li Metal Batteries Over Traditional Batteries

- Strategies for Enhancing Charge/Discharge Cycles in Li Metal Batteries

- Innovative Materials for Improved Li Metal Battery Performance

- Best Practices for Manufacturing Li Metal Batteries Efficiently

- Future Trends in Li Metal Battery Research and Applications

- FAQS

- Conclusion

- Related Posts

The rapid evolution of energy storage technology has fueled interest in innovative solutions such as Li Metal Battery technology, which promises to significantly enhance performance and efficiency. As the global lithium-ion battery market is projected to reach over $100 billion by 2025, advancements in battery chemistry are critical for meeting rising demand across various sectors, including electric vehicles and renewable energy storage. Roofer Electronics Technology (Shanwei) Co., Ltd., with more than 27 years of expertise in R&D, manufacturing, and solution services for lithium batteries and energy storage systems, recognizes the paramount importance of embracing Li Metal Battery technology. This technology potentially offers higher energy densities and longer life cycles compared to traditional lithium-ion batteries, making it an exciting prospect for applications ranging from household energy storage to electric bicycles. By leveraging our extensive experience, Roofer aims to lead the charge in optimizing efficiency through innovative battery solutions that can meet the challenges of today's energy landscape.

Understanding Li Metal Battery Technology Fundamentals

Lithium metal battery technology is transforming the energy landscape with its potential to deliver higher energy densities and improved efficiency compared to traditional lithium-ion batteries. According to a recent study by the International Energy Agency, lithium metal batteries can offer up to 40% higher energy density, making them an attractive option for applications ranging from electric vehicles to portable electronics. This leap in performance can significantly extend battery life and reduce the frequency of recharges, ultimately contributing to a reduction in energy consumption and costs.

At Roofer Electronics Technology (Shanwei) Co., Ltd., with over 27 years of expertise in lithium battery R&D and manufacturing, we recognize the transformative potential of this technology. Our products aim to replace outdated lead-acid batteries while addressing the rising demand for efficient power solutions across various sectors, including household energy storage and electric mobility. By harnessing innovative advancements in lithium metal technology, we support green energy initiatives and empower consumers to transition toward more sustainable energy alternatives. As industries evolve, the focus on lithium metal batteries will only intensify, further solidifying their role in shaping the future of energy storage systems.

Advantages of Li Metal Batteries Over Traditional Batteries

Li metal batteries are emerging as a revolutionary alternative to traditional lithium-ion batteries, largely due to their enhanced energy density and efficiency. According to a report by the U.S. Department of Energy, Li metal batteries can achieve a specific energy of over 400 Wh/kg, significantly surpassing the typical 150-250 Wh/kg of conventional lithium-ion batteries. This increased capacity not only translates to longer battery life but also reduces the overall weight and volume of battery systems, making them particularly advantageous for electric vehicles and portable electronics.

Moreover, Li metal batteries demonstrate superior charge-discharge rates, which can improve operational efficiency in various applications. Research from the National Renewable Energy Laboratory indicates that these batteries can sustain fast charging without compromising their lifespan, unlike traditional batteries that face degradation after repeated rapid cycling. With lower chances of dendrite formation, Li metal batteries also offer enhanced safety, mitigating risks associated with battery failures. This combination of higher energy output, faster charging capabilities, and improved safety makes Li metal technology a promising frontier in energy storage solutions, positioning it as a key player in the transition towards more efficient energy systems.

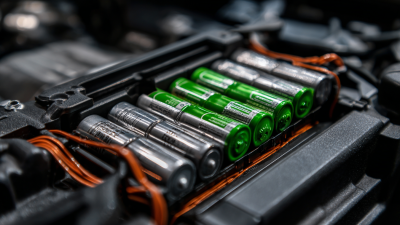

Strategies for Enhancing Charge/Discharge Cycles in Li Metal Batteries

Maximizing the efficiency of lithium (Li) metal batteries hinges significantly on enhancing the charge/discharge cycles, which can lead to improved energy density and longer lifespans. Leading research from the International Energy Agency suggests that Li metal batteries have the potential to achieve energy densities exceeding 300 Wh/kg, substantially outpacing conventional lithium-ion batteries, which typically hover around 150 Wh/kg. To harness this potential, it's essential to optimize the electrolyte composition and implement advanced surface coatings on the lithium anode, which can mitigate dendrite formation during charging cycles.

Recent studies have shown that incorporating solid-state electrolytes can remarkably improve the cyclability of Li metal batteries. For example, a report published in the Journal of Power Sources highlighted that the integration of a garnet-type solid-state electrolyte can enhance the cycle life by up to 50% while maintaining high current rates. Additionally, modifying the interface between the anode and electrolyte with interfacial layers can significantly reduce resistance and improve overall conductivity. These strategies are vital for achieving sustainable usage and performance stability in next-generation battery technologies, making them integral to the ongoing evolution of energy storage solutions.

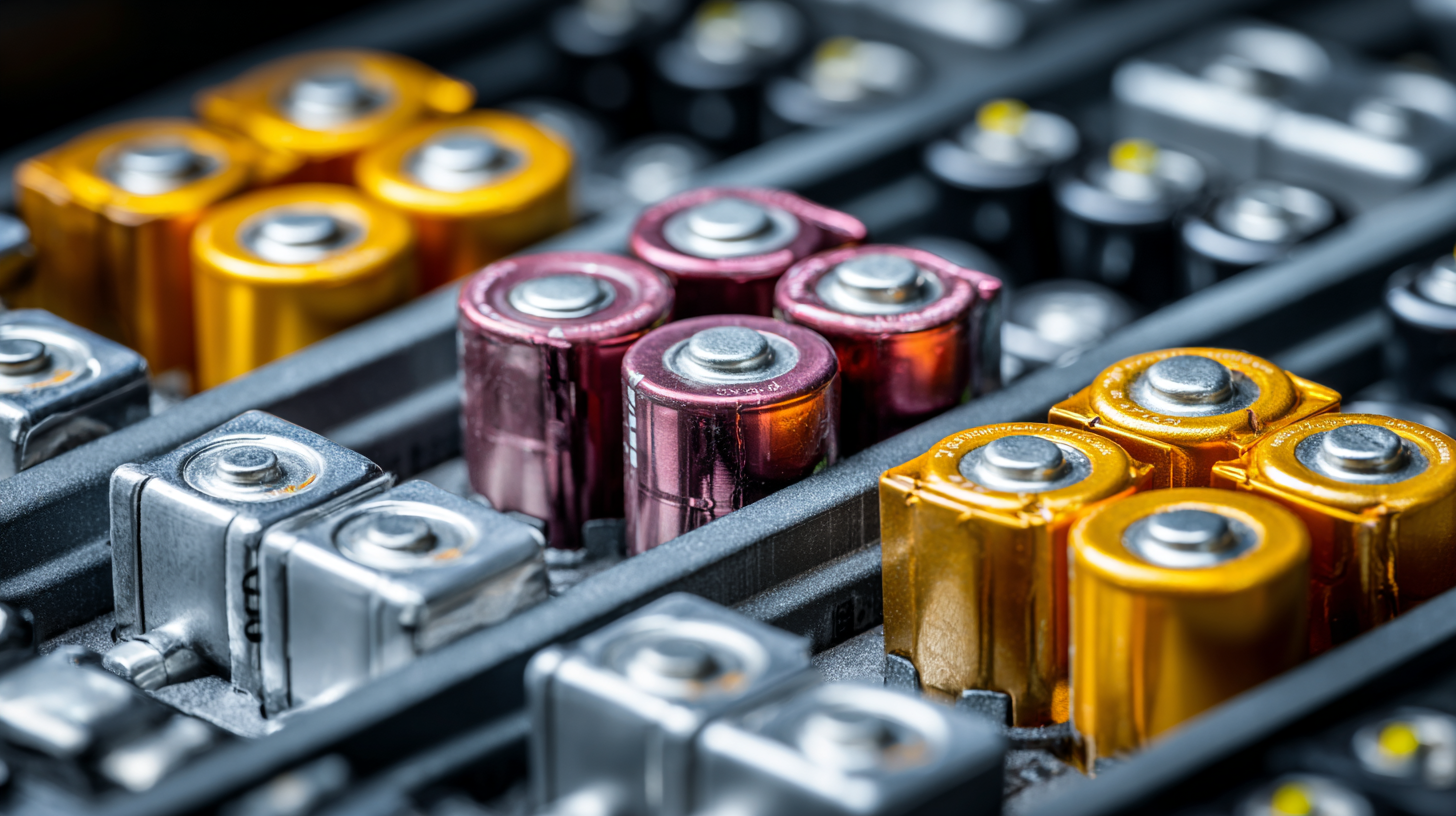

Innovative Materials for Improved Li Metal Battery Performance

Recent advances in Li metal battery technology are revolutionizing energy storage solutions, driven largely by the development of innovative materials. According to a report by the International Energy Agency, Li metal batteries can offer energy densities up to 500 Wh/kg, significantly higher than traditional lithium-ion batteries, which typically range from 150 to 250 Wh/kg. This breakthrough is primarily attributed to the use of next-generation materials such as solid electrolytes and advanced coating technologies, which mitigate dendrite formation and enhance cycle life.

To maximize the performance of Li metal batteries, consider implementing the following tips: First, invest in solid-state electrolytes that can support higher voltage operation, which directly correlates with increased battery efficiency. Companies like Solid Power and QuantumScape are leading the charge in this area, showcasing how innovative materials can dramatically improve battery safety and longevity. Second, explore the use of composite anode materials that blend Li metal with carbon or silicon substrates, which can help distribute stress and reduce degradation over time.

The integration of these advanced materials not only boosts the performance of Li metal batteries but can also make them a more viable option for electric vehicles and large-scale energy storage. As the market moves towards sustainable energy solutions, leveraging cutting-edge materials will be crucial in overcoming the current limitations associated with traditional lithium-ion technologies.

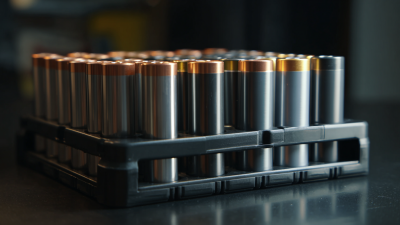

Best Practices for Manufacturing Li Metal Batteries Efficiently

To manufacture Li metal batteries efficiently, it is crucial to focus on several best practices throughout the production process. First and foremost, optimizing the electrode design can significantly enhance performance. By using advanced materials and techniques, manufacturers can create thinner electrodes with higher surface areas, allowing for better lithium ion storage and faster charge and discharge rates. Additionally, implementing a controlled deposition process can help achieve a uniform lithium layer, reducing the risk of dendrite formation and improving battery longevity.

Another critical aspect is the integration of robust quality control measures. Real-time monitoring of the production environment, including temperature and humidity, can prevent defects that may compromise battery performance. Furthermore, employing automated systems for material handling and assembly can reduce human error and increase precision. This not only speeds up production but also ensures consistency in the manufacturing process, leading to higher yields and more reliable batteries. By prioritizing these practices, manufacturers can maximize the efficiency of their Li metal battery production, ultimately contributing to the advancement of battery technologies.

Efficiency Metrics for Li Metal Battery Manufacturing

Future Trends in Li Metal Battery Research and Applications

The landscape of energy storage is evolving rapidly, with lithium metal battery (LMB) technology at the forefront of this revolution. Future trends in LMB research indicate a strong focus on enhancing the battery's energy density and cycle life. Researchers are exploring innovative electrolyte solutions and protective coatings to prevent dendrite formation, a major challenge that has hindered the commercialization of LMBs. These advancements aim to make lithium metal batteries not only safer but also significantly more efficient, paving the way for their application in electric vehicles and renewable energy systems.

Another key area of development in LMB technology is the integration of artificial intelligence and machine learning in battery management systems. By harnessing these advanced computational techniques, researchers aim to optimize charging cycles and predict battery degradation, ultimately extending the lifespan of LMBs. Additionally, collaborations between academia and industry are becoming increasingly common, driving the translation of research breakthroughs into practical applications. As investment in this technology grows, the potential for lithium metal batteries to revolutionize various sectors, from consumer electronics to grid storage, appears more promising than ever.

FAQS

: Lithium metal batteries offer up to 40% higher energy density, achieving a specific energy of over 400 Wh/kg compared to the typical 150-250 Wh/kg of conventional lithium-ion batteries. This results in longer battery life, reduced weight and volume, superior charge-discharge rates, and improved safety due to lower chances of dendrite formation.

By providing higher energy densities and faster charging capabilities, lithium metal batteries can extend battery life and reduce the frequency of recharges. This ultimately contributes to lower energy consumption and costs.

Dendrite formation can lead to battery failures and safety risks. Lithium metal batteries have lower chances of dendrite growth, which enhances their safety and longevity compared to traditional batteries.

Key best practices include optimizing electrode design using advanced materials, implementing controlled deposition processes for uniform lithium layers, integrating robust quality control measures, and employing automated systems to improve precision and reduce human error.

Lithium metal batteries can sustain fast charging without degrading their lifespan, whereas traditional batteries often face degradation after repeated rapid cycling.

Lithium metal batteries are highly suitable for a range of applications, including electric vehicles and portable electronics, due to their higher energy density and improved efficiency.

Robust quality control measures, such as real-time environmental monitoring and automated material handling, help prevent defects, enhance the consistency of the manufacturing process, and ensure higher yields of reliable batteries.

By replacing outdated lead-acid batteries and providing efficient power solutions, lithium metal batteries support the transition toward sustainable energy alternatives, thereby aligning with green energy initiatives.

As industries evolve, the focus on lithium metal batteries will increase, solidifying their role in enhancing energy storage systems and contributing to more efficient energy solutions for various sectors.

Conclusion

In the quest to maximize efficiency in energy storage solutions, Li Metal Battery technology stands out as a promising advancement over traditional lithium-ion systems. Understanding the fundamentals of Li Metal Batteries reveals their potential to deliver higher energy densities and longer cycle life. Roofer Electronics Technology, with over 27 years of expertise in lithium battery R&D and manufacturing, is well-positioned to innovate within this realm, leveraging strategic approaches to enhance charge/discharge cycles and incorporating innovative materials that boost performance.

By adopting best practices in manufacturing and staying attuned to future trends in Li Metal Battery research, Roofer aims to push the boundaries of what is possible in household energy storage and various applications like electric bicycles and power tools. The transition toward Li Metal Battery technology not only represents a shift in battery design but also offers significant advantages for sustainable energy solutions in multiple sectors.

Related Posts

-

Advantages of Utilizing Battery Solar Lithium 51.2v Lithium Solar Battery for Sustainable Energy Solutions

-

2025 Solar Powered Generator Trends and Comparisons to Watch for in the Industry

-

How to Optimize Your Lifepo4 Battery Rack for Maximum Efficiency

-

Your Ultimate Guide to Selecting Battery Racks for Optimal Performance and Safety in Energy Storage Systems

-

How to Maximize Efficiency with Your Lithium Ion Battery Pack

-

Ultimate Guide to Choosing the Right Solar Lithium Battery for Your Energy Needs

business@roofer.cn

business@roofer.cn +86 13502883088

+86 13502883088