How to Optimize Your Lifepo4 Battery Rack for Maximum Efficiency

Table of Contents

- Understanding Lifepo4 Battery Basics for Optimal Setup

- Choosing the Right Materials for Your Battery Rack Construction

- Designing Efficient Layouts for Maximum Space and Heat Dispersion

- Implementing Smart Charging Solutions for Lifepo4 Batteries

- Regular Maintenance Practices to Ensure Peak Performance

- Monitoring and Troubleshooting: Key Indicators of Efficiency Loss

- FAQS

- Conclusion

- Related Posts

As the demand for efficient energy storage solutions continues to rise, optimizing your Lifepo4 Battery Rack has become paramount for both residential and commercial applications. According to a report by the International Energy Agency, global energy storage capacity is expected to reach 1,000 GWh by 2040, driven by advancements in lithium battery technology and growing adoption in various sectors.

Roofer Electronics Technology (Shanwei) Co., Ltd., with over 27 years of experience in R&D, manufacturing, and solution services for lithium batteries, understands the unique challenges and opportunities presented by Lifepo4 systems. Our expertise spans a diverse range of applications including household energy storage, lead-acid replacement, and electric bicycles, enabling us to provide tailored solutions that enhance the efficiency and reliability of your Lifepo4 Battery Rack.

This blog will explore key strategies and common problems related to optimizing battery racks, ensuring maximum performance and longevity.

Understanding Lifepo4 Battery Basics for Optimal Setup

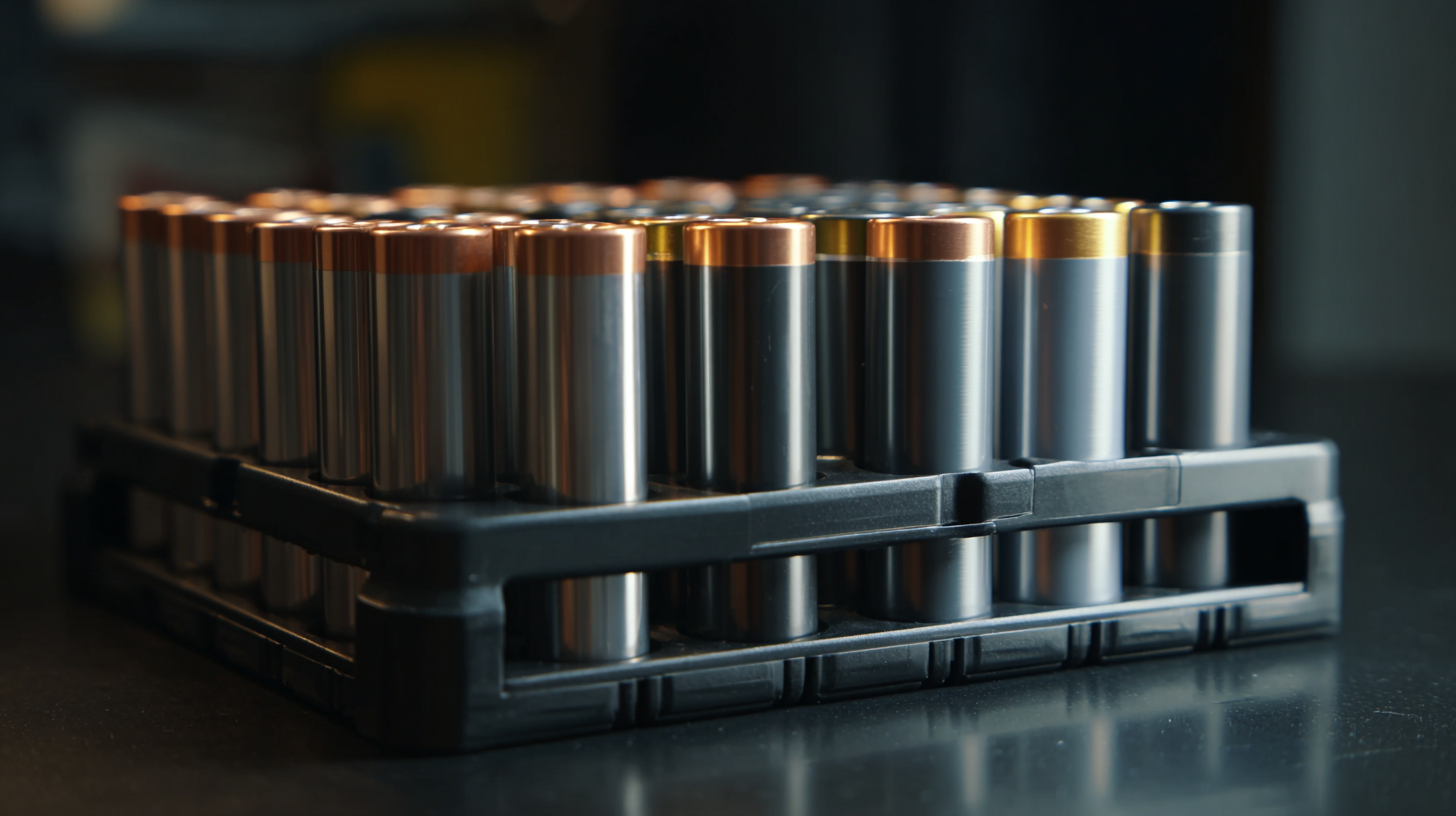

When setting up a Lifepo4 battery rack, understanding the basic characteristics of Lifepo4 technology is crucial for achieving optimal performance. Lifepo4, or lithium iron phosphate, is known for its stable chemistry, long cycle life, and excellent thermal stability. This means that Lifepo4 batteries can safely operate in a wide range of temperatures without significant degradation, making them ideal for various applications, from solar energy storage to electric vehicles. By familiarizing yourself with these fundamentals, you can create a setup that maximizes the efficiency and lifespan of your batteries.

Another key aspect of optimizing your Lifepo4 battery rack is ensuring proper configuration and maintenance. Lifepo4 batteries should ideally be grouped in series or parallel formations to match the voltage and current requirements of your specific application. Proper sizing of the battery rack is equally important; overcrowding can lead to overheating, while too much space can result in inefficient energy use. Additionally, regularly checking connections, ensuring adequate ventilation, and utilizing appropriate charging equipment will contribute significantly to the overall efficiency of your setup. By focusing on these basic principles, you can achieve a well-optimized Lifepo4 battery system that meets your energy needs efficiently.

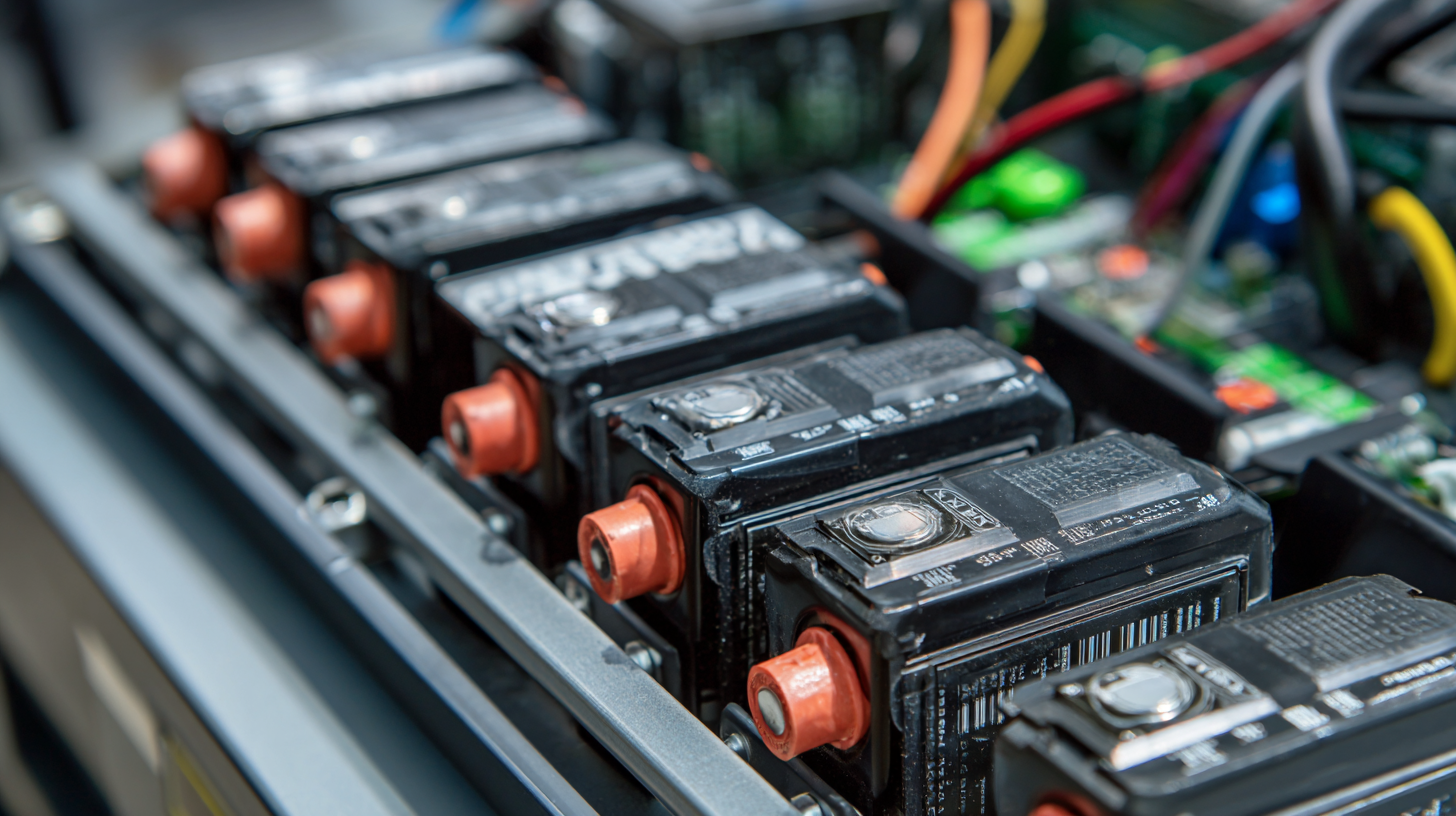

Choosing the Right Materials for Your Battery Rack Construction

When it comes to optimizing your Lifepo4 battery rack, selecting the right materials for construction is crucial. The integrity and durability of your battery rack play a significant role in overall system performance. Start by considering aluminum or stainless steel for the frame, as both materials offer excellent corrosion resistance and structural strength. Aluminum is lightweight, which can be beneficial for portability, while stainless steel provides added robustness, particularly in harsh environments. Be sure to choose materials that withstand the temperature fluctuations often experienced in battery storage.

In addition to the frame, the insulation and padding materials should not be overlooked. Using high-density foam or rubber can help mitigate vibrations and provide thermal insulation, protecting the batteries from extreme temperatures. It’s also essential to incorporate materials that are non-conductive to prevent short circuits and ensure safety. Furthermore, choose a finish that enhances longevity, such as powder coating, to further protect against elements that could degrade the rack over time. By carefully selecting these materials, you not only enhance efficiency but also extend the lifespan of your Lifepo4 battery system.

Designing Efficient Layouts for Maximum Space and Heat Dispersion

When optimizing your Lifepo4 battery rack, focusing on the layout is crucial for achieving maximum efficiency and effective heat dispersion. A well-designed layout not only maximizes space but also enhances thermal management, which is essential for maintaining battery performance and longevity. Recent studies highlight the importance of utilizing advanced designs, such as vertical and spiral fins, to control airflow and effectively dissipate heat. By strategically positioning battery cells and optimizing airflow patterns, users can prevent overheating and ensure that each cell operates within its optimal temperature range.

In the realm of energy storage systems, Roofer Electronics Technology has been at the forefront for over 27 years, developing innovative solutions for lithium batteries. Incorporating principles from thermal management studies into their designs, Roofer prioritizes efficient layouts that promote heat dispersal. By employing concepts from computational fluid dynamics and structural design advancements, they create battery racks that not only save space but also maximize cooling, thus enhancing overall system efficiency. As battery technology continues to evolve, embracing these design principles will prove vital for optimizing performance and reliability in various applications, from household energy storage to electric vehicles.

Implementing Smart Charging Solutions for Lifepo4 Batteries

Implementing smart charging solutions for LiFePO4 batteries is essential for maximizing efficiency and enhancing the longevity of battery systems. Recent studies indicate that optimizing charging algorithms can lead to a reduction of charging time by up to 30% while minimizing battery degradation. The integration of smart charging technologies allows for real-time monitoring and control, ensuring that the batteries operate within their optimal parameters. This is particularly crucial in commercial applications where downtime can equate to significant financial losses.

Moreover, adopting smart charging can promote energy conservation. According to a report by the International Energy Agency (IEA), the effective use of smart charging systems can yield energy savings of approximately 15-20% in large-scale battery storage systems. These solutions facilitate the use of renewable energy sources by intelligently scheduling charging during periods of low demand or high energy generation. By utilizing such strategies, businesses can not only enhance their operational efficiency but also contribute to a more sustainable energy ecosystem.

Optimization of Lifepo4 Battery Efficiency

Regular Maintenance Practices to Ensure Peak Performance

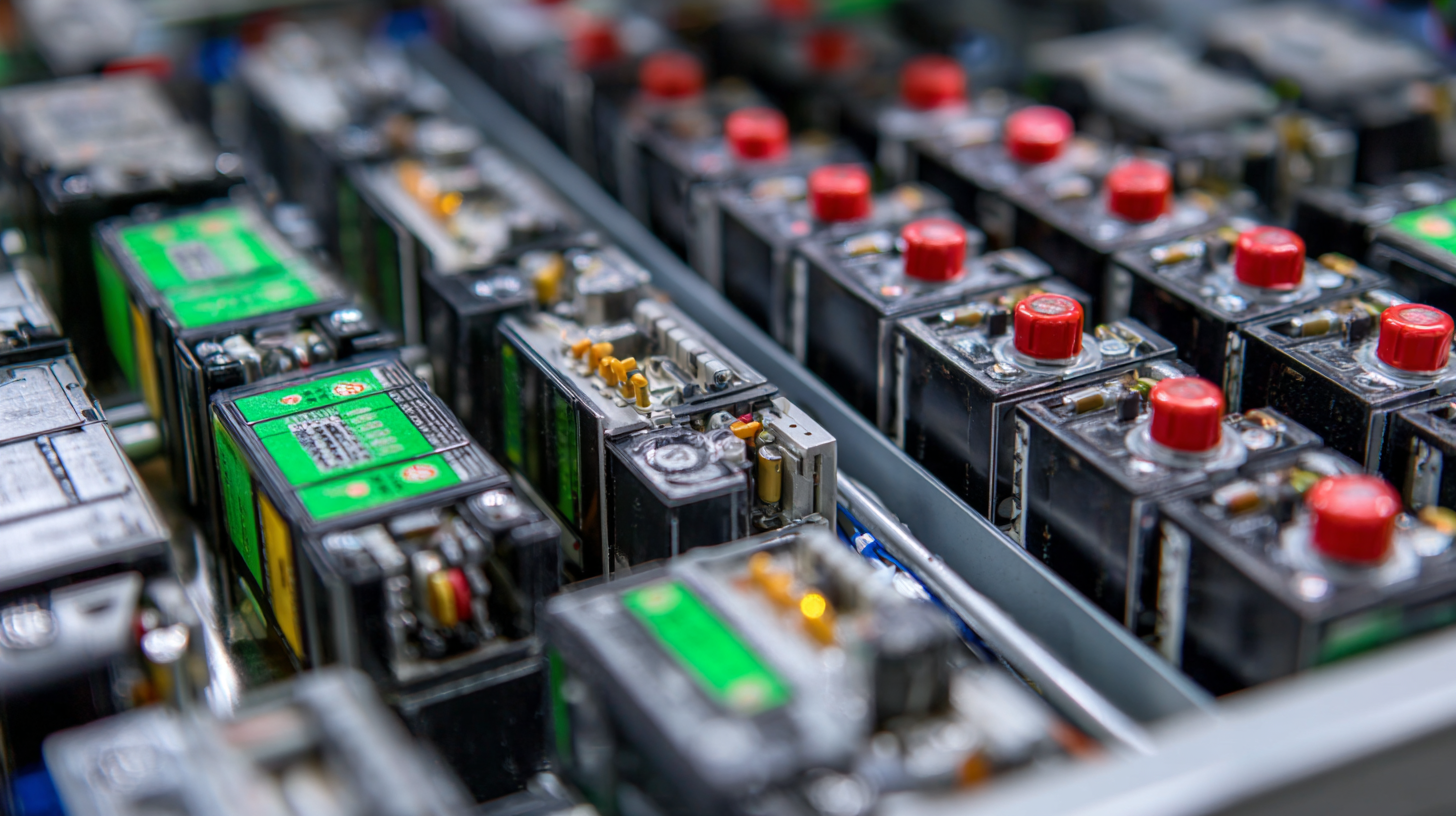

Regular maintenance is crucial for ensuring that your Lifepo4 battery rack operates at peak performance. One of the first steps in your maintenance routine should be to regularly inspect the physical condition of the batteries. Look for any signs of corrosion, swelling, or leaks, as these can indicate potential issues that may affect efficiency. Cleaning the terminals and connectors with a mixture of baking soda and water can help prevent corrosion buildup, ensuring a good electrical connection.

Additionally, monitoring the battery's temperature is essential. Lifepo4 batteries perform best within a specific temperature range, typically between 20°C and 25°C. Install temperature sensors if possible, and ensure proper ventilation around the battery rack to avoid overheating. Regular voltage checks will also keep you informed about the health of each individual cell. An imbalance in voltage can lead to reduced performance and lifespan, so it’s advisable to balance the batteries periodically to maintain uniformity and efficiency throughout your system.

Monitoring and Troubleshooting: Key Indicators of Efficiency Loss

Monitoring the efficiency of your Lifepo4 battery rack is crucial for ensuring optimal performance and longevity. Key indicators of efficiency loss often stem from thermal management, voltage imbalances, and charge-discharge cycles. Research has shown that maintaining battery temperatures within a range of 15-35°C can improve efficiency by up to 20%. Additionally, regular monitoring of cell voltage can help identify imbalances that may lead to reduced capacity. A report from the International Energy Agency (IEA) indicates that proper voltage regulation can enhance the lifespan of lithium batteries significantly, reducing costs over time.

At Roofer Electronics Technology (Shanwei) Co., Ltd., we leverage over 27 years of expertise in R&D and manufacturing to provide innovative energy solutions. Our insights into the lithium battery industry highlight the importance of real-time monitoring systems that track performance metrics. According to a recent industry analysis, battery management systems (BMS) equipped with predictive analytics can detect performance degradation early, allowing for proactive maintenance that can save up to 30% in operational costs. This not only extends the life of the batteries but also ensures that your energy storage systems function at peak efficiency in various applications, from household energy solutions to electric vehicles.

FAQS

: Aluminum and stainless steel are recommended for the frame due to their corrosion resistance and structural strength. Aluminum is lightweight for portability, while stainless steel offers robustness in harsh environments.

Insulation and padding help mitigate vibrations and provide thermal insulation, protecting batteries from extreme temperatures.

Using non-conductive materials in the construction of the battery rack can prevent short circuits and enhance safety.

Utilizing advanced designs, such as vertical and spiral fins, can improve airflow control and effectively dissipate heat, enhancing battery performance and longevity.

Roofer Electronics Technology employs principles from thermal management and computational fluid dynamics to create efficient layouts that maximize cooling and save space.

Smart charging solutions can reduce charging time by up to 30%, minimize battery degradation, and promote energy conservation with potential savings of 15-20% in large-scale battery systems.

They enable real-time monitoring and control, ensuring batteries operate within optimal parameters, which is crucial in commercial applications.

Smart charging can intelligently schedule charging during low demand or high energy generation periods, facilitating the effective use of renewable energy sources.

A well-optimized layout enhances thermal management by strategically positioning battery cells and promoting optimal airflow patterns, preventing overheating.

Powder coating enhances the longevity of the battery rack by protecting it against degrading elements and environmental factors.

Conclusion

In the quest to optimize your Lifepo4 Battery Rack for maximum efficiency, it's essential to start with a solid understanding of Lifepo4 battery fundamentals, which will help inform your setup. Choosing the right materials and designing an efficient layout are crucial steps that ensure not only optimal space utilization but also effective heat dispersion. Implementing smart charging solutions can significantly enhance battery life, while regular maintenance practices keep performance at peak levels.

Moreover, monitoring key indicators of efficiency loss allows for timely troubleshooting, ensuring that your Lifepo4 Battery Rack operates at its best. At Roofer Electronics Technology, with over 27 years of experience in lithium batteries and energy storage systems, we emphasize the importance of these practices in both residential and commercial applications, ultimately leading to a more reliable and sustainable energy solution.

Related Posts

-

Future Innovations in Best Solar Generating Stations for 2025 a Comprehensive Guide to Next Generation Technologies

-

Your Ultimate Guide to Selecting Battery Racks for Optimal Performance and Safety in Energy Storage Systems

-

Advantages of Utilizing Battery Solar Lithium 51.2v Lithium Solar Battery for Sustainable Energy Solutions

-

Ultimate Guide to Understanding Lifepo4 Battery Cell Technology and Its Benefits for Modern Energy Solutions

-

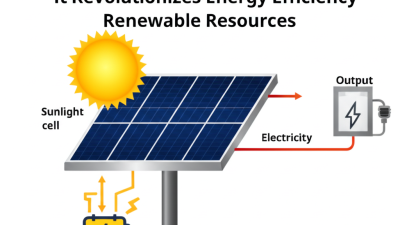

What is a Solar Cell Generator and How It Revolutionizes Energy Efficiency in Renewable Resources

-

Understanding the Industry Standards for Best 12v Lithium Iron Battery Production

Blog Tags:

business@roofer.cn

business@roofer.cn +86 13502883088

+86 13502883088